1-Measure

Measure plate for each type of enclosure

Each measure plate contains :

– Measurement on CE61010 plug (Diam 4mm)

Allowable current: 20A

Terminal block section: 2.5mm² to 35mm²

– Insulating PVC support Removable shunt jumper

This type of plate is used to perform measurement on cathodic protection system.

It is used to to have connections with measurement accessories and to measure the efficiency of the cathodic protection.

Waterproof measuring tip

This type of waterproof IP 67 measuring tip fits perfectly on cathodic protection cables.

For cable sections from 2.5mm² to 16mm², allowing potential measurement.

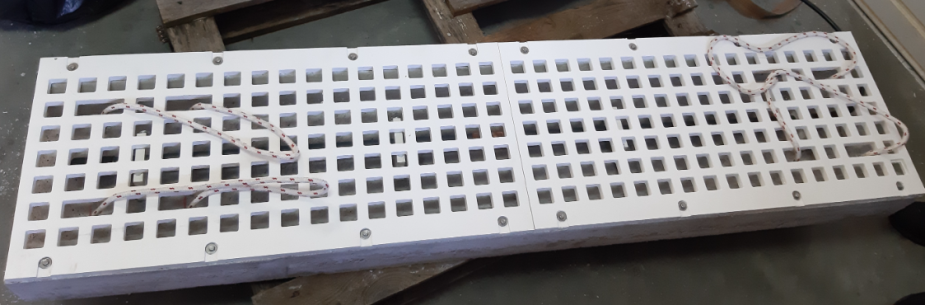

Measuring box with jumper (number of channels upon request)

Allowable current in a jumper: 20A max. Section of connection cables: Flexible PC 10²

Cable sealing using low shrinkage epoxy resin. Measurement on IEC61010 plugs (Diam 4mm).

Link cut-off jumpers fit into keyholes. They are intended to make electrical connections. (rectifier/anode, PP/TM, insulating gasket, etc.) They are IP67 waterproof. Safety sockets (IEC 1010) are used to carry out quick and simple measurements by connecting standardized IEC 1010 leads. Each channel can be connected to different elements: pipe, metal indicator, permanent electrode, potential tap, etc.

Metallic indicator

Removable indicators allow measurements and recordings to be made on structures subject to cathodic protection.

The surface indicator for manhole installation is intended to be installed permanently in manholes.

The indicator associated with a measuring well is intended to be placed near the pipe, and to be left permanently. It is associated with a DN 50 well to be able to slide an electrode into it.

2 – Anodes

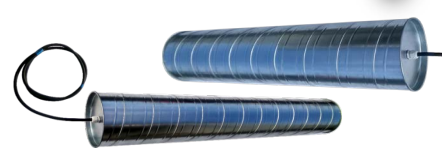

Ti/MMO alloy anode in strings

Titanium anodes electrocatalyzed by a mixed metal oxide (MMO) coating have the advantage of being able to withstand a high cathodic protection current.

MMO titanium anodes consist of a titanium substrate coated with a mixture of precious metal oxides, typically including iridium, ruthenium and tantalum. The titanium substrate used in MMO anodes is highly resistant to corrosion, even in aggressive environments. This inherent strength helps protect the anode from degradation over time, contributing to its longevity.

The mixed metal oxide coating on the titanium substrate is designed to be stable and wear resistant. This coating retains its catalytic properties over extended periods, ensuring consistent performance throughout the life of the anode.

Anode mounted on a concrete base

Magnesium alloy anode

Fe-Silicium alloy anodes : Bare and Prebackfilled

Titane plated anode / Zinc anodes

Backfill